Piezo OEM Development Solutions

Partner with our our piezo experts in a collaborative engineering process to design and build a reliable and robust piezoelectric sub-system solution.

Piezo.com offers engineering services for custom piezoelectric OEM component development. Our experienced piezo experts eliminate potential design flaws which plague those unfamiliar with piezoceramic technology, especially in the areas of lamination bonding, flexure design, ceramic stress and fatigue criteria, thermal stability, mounting, power take-off attachments, electronic drive, testing, and evaluation. This service reduces the customer’s need to dedicate highly qualified personnel during the development period, and development time is typically reduced from years to months.

Typically, a custom OEM development will be a minimum of $20,000.

Piezo.com strives to ensure success for both parties, by communicating clearly and working collaboratively through the entire process. There are three main questions we answer before proceeding to any development:

- Intellectual Property Ownership - You own the application, we own the manufacturing approach and all pre-existing IP.

- Development Process - We use a phased approach and require the effort to be funded by the customer.

- Manufacturing - We want to produce a piezo-based system in the end, ideally for a harsh environment

Intellectual Property Ownership

We will sign a mutual NDA early in the relationship and prior to starting any design effort. We know that customers will want to protect their investment and seek to have some IP ownership in the end. We want that for you too! But we have a lot of pre-existing IP in piezoelectric system design, construction, and application that we will retain and potentially leverage in the design.

Ultimately the IP ownership can be simplified to the customer owning how the piezo system is applied to their application. But we may likely develop some IP on how to reliably produce the system that can be broadly applicable that we will seek to retain and apply to non-competing other applications.

Development Process

We leverage a phased approach to buy down risk for both parties, we all know there are a lot of unknowns in an engineering effort! And we don't want to proceed with production until we "know" what we can do and how to do it. The most successful developments we've had have been collaborative efforts with the customer.

Every development effort is different, but we have done enough of these that we know generally the cost:

- $5K to $10K for a paper feasibility study

- $15K to $25K to build, test, and iterate a physical prototype

- Typically design to a working prototype in 6 to 12 weeks

- Depending on size & complexity there may be more development cycles

Manufacturing Capabilities & Intent

We are not a design-for-hire firm and will only embark on a development process when there is an opportunity to make something in the end.

Piezos are complex and with our expertise, we are able to repeatably and reliably manufacture a robust sub-system that can be easily integrated into the end customer’s application/system. The harsher the environment, the more excited we become!

Again the costs are highly dependent on the system but we know we will generally be in these ranges:

- Producing between 100 and 50,000 units annually

- Per unit cost between $20 and $1,000

Again pricing is dependent on a variety of factors but it is important for us to be transparent that with our manufacturing process, we are unable to achieve per unit prices below $20, regardless of size/shape, even at high volumes. We have been able to provide certain piezo systems to customers for less than $20, but certainly not less than $10. If your application requires prices below $10 and volumes above 50,000 units unfortunately we are unlikely to be the right partner for you - but we wish you luck!

Let's Start a Discussion!

We'd love to set up a time for you to learn more about our capabilities and for our engineers to learn more about your application to determine if we can help. We look forward to talking with you soon and learning of another new application for piezos!

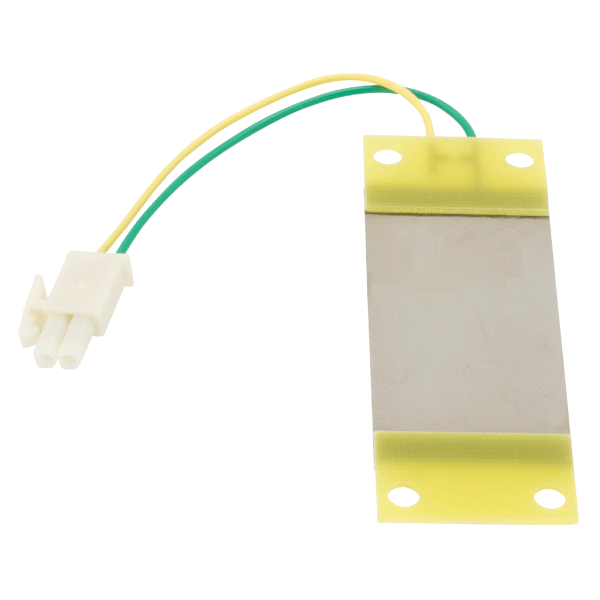

Selection of Current OEM Products

The following is a sampling of some of our current OEM products. This helps illustrate the range of designs we support in addition to our production capacity - we can produce over ten thousand of your custom parts annually, or as little as ten depending on your application's needs.

| Product | Description | Annual Quantity |

|---|---|---|

|

Ultrasonic Sensor | 100+ |

|

Dual Valve Actuator With Two Piezo Benders | 10,000+ |

|

Bending Valve Actuator | 1,000+ |

|

Ultrasonic Probe Actuator | 100+ |

|

High Precision Strain Sensor | 1,000+ |

|

Fixed Beam Valve Actuator | 1,000+ |

| Resonance Tracking & Amplifier Electronics | 100+ |