Piezo.com are experts in Piezo Ultrasonic Solutions! We have collectively over 100 years of experience designing and manufacturing piezoelectric systems. We have a firm understanding of many engineering applications and access to a diverse engineering team. We love working with our customers to find new and exciting ways to apply piezoelectric technology to solve engineering problems!

Ultrasonic Applications

Ultrasound is sound waves with frequencies greater than the audible range of humans, or about 20 kHz. Ultrasonic devices can generate sound waves and vibrations from 20 kHz up to the gigahertz range.

These high frequency waves can excite materials in interesting and valuable ways. There are many existing applications for ultrasonics and more applications are found every day.

Common Transducer Applications Include:

- Motion Sensors

- Flow Sensors

- Non destructive testing

- Medical Imaging

- Cutting

- Cleaning

- Atomization

Piezoelectrics are a unique class of materials which when deformed by applied stress produce usable electric charge and when subjected to an applied electric field can deform themselves.

Piezoelectrics and ultrasonics are inherently linked as piezoelectrics are an enabling technology for ultasonics due to their high frequency response and ability to be designed into a range of different devices.

The most common piezoelectric materials are lead zirconate titanate (PZT). PZT’s are ceramics and have very good piezoelectric properties. However, if not designed or protected well PZT’s, due to their being ceramics, can be brittle and have failure issues, specifically when loaded in tension.

At piezo.com we have two different technologies to drastically improve the robustness of bare PZT materials. One technology involves bonding the PZT material to a metal shim with a very durable and high strength bond. This technology provides a good amount of mechanical protection for the PZT.

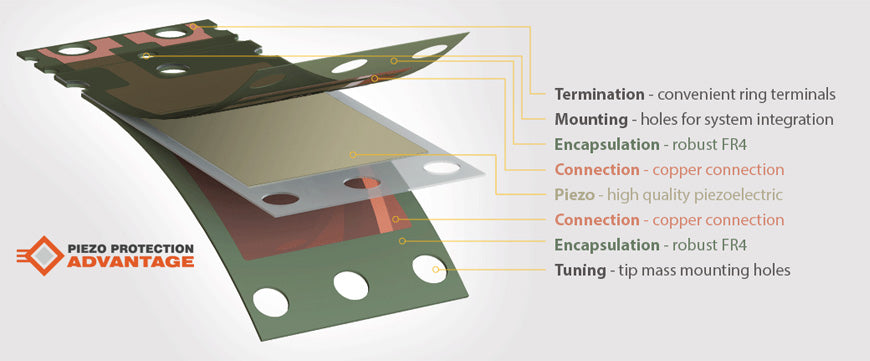

The second technology involves a full encapsulation of the PZT material using copper clad and etched materials. This encapsulation, or as we call it “packaging”, protects the PZT both mechanically as well as from the environment. Etching of the copper clad materials also allow for full customization of the electronic circuit needed to robustly connect the PZT to its drive, sensing or harvesting electronics.

Some of our ulstrasonic developments are for hand held tools or used in an industrial environment. Proper design as well as utilizing our technologies for improving robustness are critical to successful developments.

Find out More About Our: Piezoelectric Packaging Advantage

Both piezoelectrics and ultrasonics are complex by nature. Successful developments of new products and solutions using piezoelectrics for any application, but specifically for ultrasonics requires expertise and experience. We have both at Piezo.com. We have successfully worked with customers to design robust and reliable ultrasonic devices and systems.

Ultrasonic Probe Actuator: A customer needed an ultrasonic probe actuator for the use in a harsh outdoor environment to excite a liquid. They needed not only the piezoelectric actuator but the entire probe assembly with integrated wires.

Ultrasonic Sensor: A customer needed a highly accurate and dependable ultrasonic sensor for use in a steam trap testing tool. It needed to be an improved version of what they were currently using and work with their analysis software.

If you would like to meet with one of our Ultrasonic experts to discuss potential Development Partnerships, please fill out the form and we'll organize a meeting.